In November 2018, Casey Industrial wrapped up construction on the installation of four Wärtsilä 50SG reciprocating engines at the Arvah B. Hopkins Generating

Station in Tallahassee, Florida. Following the success of the original project, the City of Tallahassee awarded Casey Industrial an expansion project involving the complete installation of a fifth Wärtsilä 50SG engine.

The Casey team has been back on site and diligently working toward completion since June 2019. On November 27th, the team received a major delivery – the engine arrived on site. The site team and the City are very pleased with the progress being made and look forward to seeing the engine move into its final position in the engine hall alongside the other four engines.

Casey recognizes the need to move toward “grid balancing” energy options and is proud to have installed 90 Reciprocating Engines across the United States, ranging in size from 500 KW to 18 MW and providing our customers with back-up power and generation projects in the 1 MW to 200+ MW range. In a story documented by WCTV, this installation is one of several projects the City of Tallahassee is pursuing in order to provide clean, reliable energy to their residents.

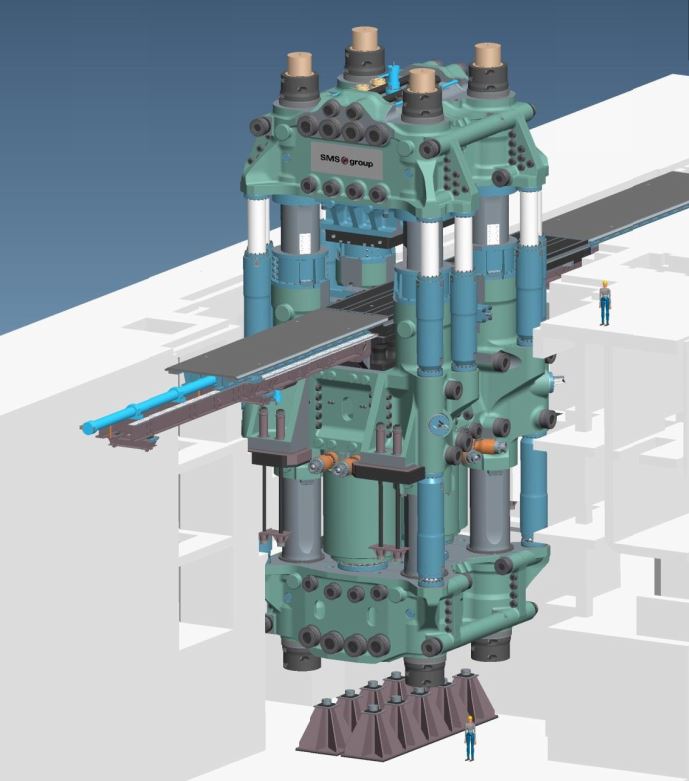

d by Weber Metals, a subsidiary of Otto Fuchs KG. This press, with a maximum pressing force of 60,000 short tons, was born from a desire to create lighter weight aerospace components. Utilizing forged aluminum and titanium, it can produce lightweight and optimized pieces to be used in the fuselage, wings, undercarriage, and engines.

d by Weber Metals, a subsidiary of Otto Fuchs KG. This press, with a maximum pressing force of 60,000 short tons, was born from a desire to create lighter weight aerospace components. Utilizing forged aluminum and titanium, it can produce lightweight and optimized pieces to be used in the fuselage, wings, undercarriage, and engines. On October 23rd, 2018, Casey’s President, Stephen Brague, and the Project Manager, Paul Kikel, attended a ribbon cutting ceremony hosted by the owner, Otto Fuchs KG, to celebrate the completion of the press. A video of the impressive unveiling can be seen

On October 23rd, 2018, Casey’s President, Stephen Brague, and the Project Manager, Paul Kikel, attended a ribbon cutting ceremony hosted by the owner, Otto Fuchs KG, to celebrate the completion of the press. A video of the impressive unveiling can be seen

Casey Industrial is excited to announce that Daniel Henke has taken the role of Vice President and will be focusing his efforts on Business Development in the Gulf Coast Region of the United States.

Casey Industrial is excited to announce that Daniel Henke has taken the role of Vice President and will be focusing his efforts on Business Development in the Gulf Coast Region of the United States.